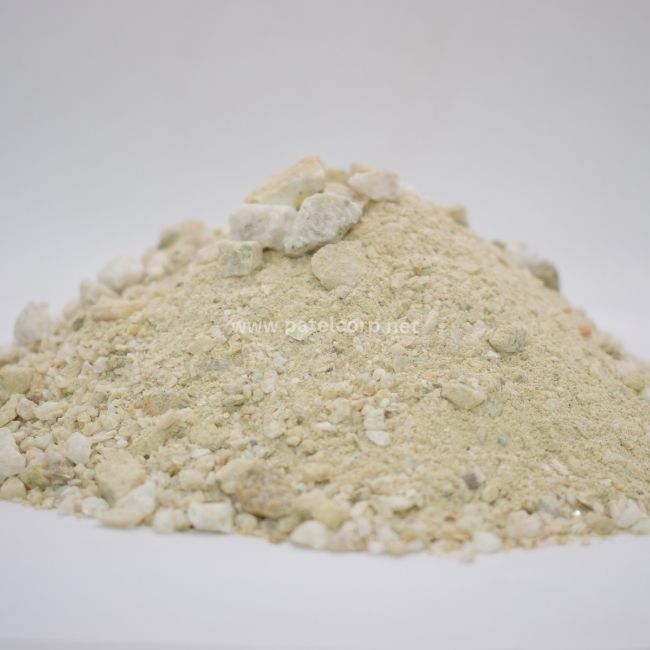

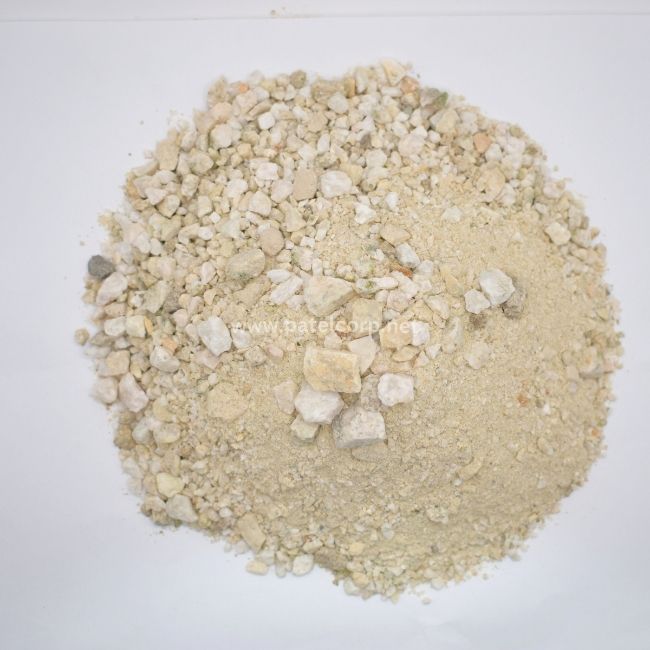

Soda Feldspar / Ceramic Grade

SODA FELDSPAR:

Product Overview:

A mineral-derived product used in ceramics and glass manufacturing, soda feldspar serves as a flux to lower the melting temperature of raw materials, promoting the formation of a glassy phase in the final product.

Ceramic Tiles Production:

A saúde sexual é uma parte importante do bem-estar geral, mas muitos homens enfrentam dificuldades nessa área. A questão pode ser mais comum do que se pensa, afetando não só a confiança, mas também a vida de casal. Existem diversas abordagens para lidar com essa situação, incluindo terapia e mudanças no estilo de vida. Para alguns, a escolha de tratamentos pode ser facilitada por recursos modernos que oferecem a conveniência de compra, como os “medicamentos com entrega online“. Esses serviços proporcionam discrição e acessibilidade, permitindo que os homens procurem ajuda sem constrangimentos. É essencial lembrar que o diálogo aberto com um profissional de saúde é o primeiro passo para encontrar a solução mais adequada.

Soda feldspar is a key component in the production of ceramic tiles. It helps in enhancing the durability, hardness, and resistance to stains and abrasion of the tiles.

Porcelain Manufacturing:

Porcelain, known for its strength and translucency, often incorporates soda feldspar as a fluxing agent. It plays a crucial role in lowering the melting temperature of the raw materials during the firing process.

Sanitary Ware Production:

In the production of sanitary ware, soda feldspar is used to improve the vitrification process, contributing to the durability and smooth finish of products like sinks and toilets.

Tableware and Dinnerware:

Soda feldspar is commonly employed in the manufacturing of tableware and dinnerware, enhancing the thermal shock resistance and overall strength of the final products.

Glaze Formulation:

It is a key component in ceramic glazes, contributing to the melt fluidity and promoting a glossy finish on the surface of ceramic items.

Ceramic Insulators:

In the electrical industry, soda feldspar is utilized in the production of ceramic insulators due to its high resistance to heat and electrical conductivity.

Abrasive Applications:

Soda feldspar’s hardness makes it suitable for use in abrasive applications, such as in the manufacturing of grinding wheels and other abrasive products.

Frits and Enamels:

It is a common ingredient in frits and enamels, which are applied to ceramic surfaces to provide color, texture, and additional protective layers.

Refining Raw Materials:

Soda feldspar acts as a fluxing agent, lowering the melting point of other raw materials in ceramic production, and facilitating the shaping and firing processes.

Artistic Ceramics:

Artists and craftsmen use soda feldspar in the creation of artistic ceramics, taking advantage of its unique properties to achieve desired textures and finishes.